QTC® is the acronym for “Quantum Tunnelling Composite”.

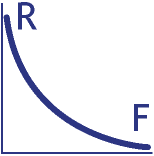

Put simply, QTC changes its electrical resistance based on changes in applied force. The more force the less resistance. This is achieved through Quantum tunnelling alongside other complementary conduction mechanisms.

Quantum tunnelling is realised by selecting the precise shape of certain conductive nanoparticles and carefully controlling the processes used to blend them with other particles.

Quantum tunnelling adds a level of control, reliability, and range to create a real-world touch experience that otherwise would not exist.

Today, QTC is produced as a screen printable polymer-based ink in opaque and transparent versions.

Peratech holds IP on formulations and materials manufacturing processes that promote Quantum Tunnelling.