POSTED BY Peratech | Jul 11, 2017 |

Richmond, Yorkshire, UK – 11 July 2017. Peratech, the force-sensing technology specialists, and SMK Electronics (SMK), a world leader in the design, development and manufacture of OEM remote controls and electronic components, today announce their collaboration to incorporate Peratech’s pioneering and award-winning Quantum Tunnelling Composites (QTC) technology in SMK’s remote control products, consumer products and automotive modules.

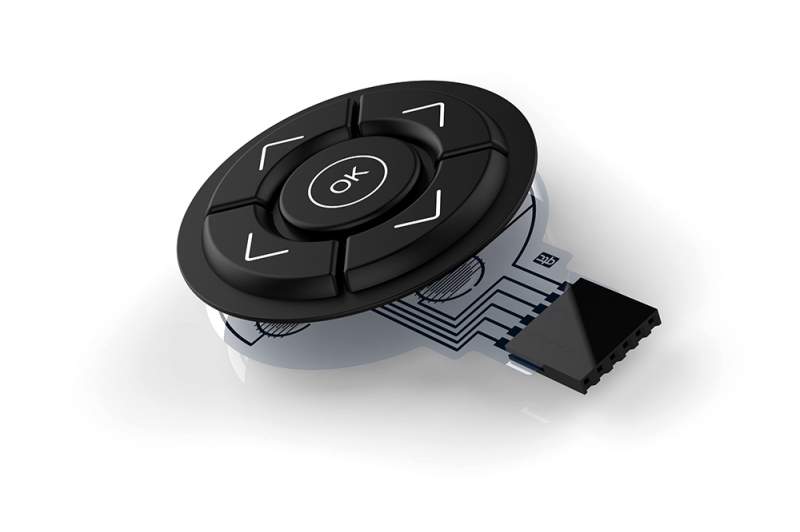

Peratech’s QTC technology enables better human-machine interfaces through the use of accurate force sensing and has already been successfully integrated into SMK’s remote control prototypes.

Incorporating QTC force-sensing technology into a remote control improves the experience of using capacitive buttons, touchpads or directional pads, by requiring a press-with-force to send commands to the receiver. This eliminates the accidental input that capacitive buttons and touchpads can be prone to. QTC also enables new, richer ways of interacting with the machine’s interface: for example, a light press to fast forward at 2x speed, medium press to fast forward at 4x speed, and hard press to skip to the next episode. Peratech’s 3D Force Touch Matrix sensors are highly energy-efficient, enabling battery lives of two to five times longer, when compared to capacitive touchpads.

QTC force-sensing technology is also ideal for automotive applications, as force touch controls can be integrated under virtually any surface found in the cockpit including glass, wood, plastic, metal and leather to create a ‘smart surface’. 3D touch sensors can be mounted under flat or curved surfaces and objects, enabling richer interactions with the car’s systems and ensuring buttons only respond when there’s genuine intent to press them.

Mike Levin, CCO at Peratech, said: “Many of us have already experienced the benefits of force-sensing technology in our smartphones and laptop trackpads. It’s a natural next step to extend this to remote controls, cars and other products that we spend a lot of time using. QTC is robust, reliable, performs predictably and can be precisely tuned to determine what constitutes a light press and a firmer press.”

Paul Evans, President of SMK Electronics added: “At SMK Electronics, we are always looking for innovative ways to improve the experiences people have when using our products. Peratech’s QTC force-sensing technology is enabling us to offer some exciting new capabilities that are already generating significant interest from our customers. We’re looking forward to helping more of our customers experience the benefits of force-sensing technology over the coming months.”

+++ends+++

Based on patented Quantum Tunnelling Composite (QTC®) technology, Peratech’s force sensors bring a new dimension to touch controls. QTC materials change from being an almost perfect insulator to becoming increasingly conductive in proportion to the amount of force applied to them. The materials are very resilient, with predictable deformation and recovery, so that changes in resistance from even the slightest pressure on the QTC material are both predictable and repeatable over more than a million cycles.

For designers of human machine interfaces (HMIs), QTC technology offers unrivalled creative freedom and opportunities for product differentiation in both ergonomics and aesthetics. It makes touch buttons, panels and displays far easier to use.

Peratech’s award-winning, thin and flexible QTC sensors come in single-point, 3D single-touch, and 3D multi-touch versions. They can be used above, below or around rigid or flexible displays, or under metal, plastic, wood or glass surfaces. The QTC touch experience is intuitive, consistent, precise, durable and reliable, whatever the environment, even when using gloved fingers or in the presence of moisture.

The diverse applications for QTC force sensors include consumer and automotive electronics, smart home systems and appliances and industrial controls. Over a million devices around the world now employ the technology. Peratech’s custom design and integration service minimises both cost and time-to-market. The company also offers a range of standard products. Peratech Holdco Ltd. is a privately held company based in Richmond, Yorkshire, UK.

Quantum Tunnelling Composite and QTC are registered trademarks of Peratech Holdco Ltd. All other trademarks are the property of their respective owners.

Peratech, Old Repeater Station, Brompton-on-Swale, North Yorkshire, DL10 7JH United Kingdom. Tel: +44 (0) 1748 813670 Fax: +44 (0) 1748 813679

Email: info@peratech.com www.peratech.com

Publitek

Rachel Sandeman, +44 (0)2038 136425, Rachel.Sandeman@publitek.com

SMK Electronics is the U.S. division of SMK Corporation, a world leader in the design, development and manufacture of OEM remote controls and electronic components. Through its local Research & Development and Manufacturing facilities, and in coordination with SMK’s R&D and Manufacturing Centers worldwide, SMK Electronics is uniquely positioned to provide the U.S. Consumer Electronics and Automotive industries with technologically advanced, robust, cost-effective products and solutions. Learn more at http://www.smkusa.com/

SMK Electronics

Keith M. Roberts, Tel: +1 805 987 6662 ext. 303 kroberts@smkusa.com